Cob and More!

....

The wonderful world of cob and all of its abilities.

Fujian Tulou, China.

Why Cob? Because cob offers the best bang for the buck and it is easy to make, structurally sound, time tested, abundantly available and the energy storing properties are amazing. First a little history. After the cave, cob is probably the oldest style of shelter built by man. They're are cob structures in Europe to this day that are hundreds of years old and are still in use and fully functional today. The Chinese have used this style of building for over a thousand years, it is known as a Tulou building in China dating back to before the Ming dynasty. Mud huts are synonymous with aboriginal tribes through out the world, you can't think of one with out the other, and to date these would be to date man kind. So I think you get the point that this is nothing new, but that we are just revisiting this ancient technology with new ideas. Cob is a mixture of clay, sand, water and some sort of fiber particle usually a grass such as straw or bark peelings used from a tree for re-enforcement in the mixture. After combining the ingredients and mixing it together you make small hand size balls that you then stack and form on top of each other in the shape of your desired project. Sounds easy huh? It is!. This process can also be used to form bricks that are dried in the sun to be stacked later , this is called Adobe and empires have been built using this method, the word itself traces back over four thousand years to Egyptian civilizations and loosely translate to "sun dried". Animal manure is usually added to the mix for strength and elasticity in hotter climates, or the compound can be rammed into pre-made forms, this is called rammed earth style.

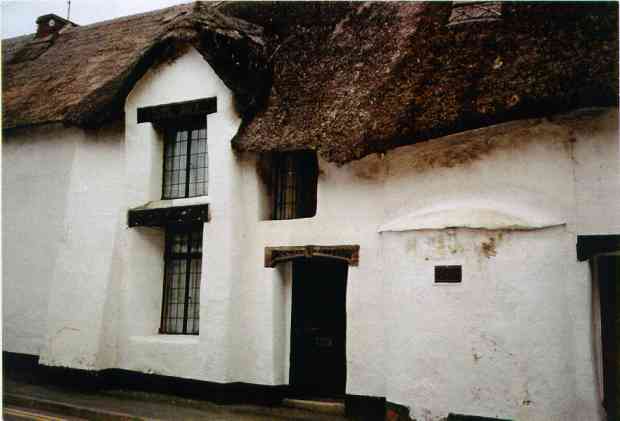

So as you can see by these pictures Cob is a beautiful, creative, self-sustaining and ECO-nomically responsible way of building. Cob has made a comeback over the last ten to twenty years as a viable and sustainable way of building. I think more for the fact that it is so cheap above all other reasons was the driving force, but as these beautiful mud mansions sprung up around North America it has become more evident that they are more then cheap to build but that the list of benefits goes far beyond this. First being the abundance off raw materiel available to build with that doesn't involve any fossil fuels to process, Second is the ECO-nature of the dwelling itself, the compounds used are in harmony with earth and don't experience the wild temperature swings of the seasons, Warm in the winter and cool in the summer, cob is an extension of the planet itself. Regular Cob offers about R 4-6 insulative properties. Then there is the creativity effect, you're virtually at the will of you imagination, there are not many rules that you have to follow other then basic common sense structural and weight bearing needs. The laws of physics are still at work and still apply, but things like right angles and linear dimensions are out the window. You can curve and cove your little heart out, you don't even need a corner anywhere in the hole project if you don't want one. A lot of of aboriginal peoples never used corners on their buildings because they believed that corners stopped the flow of energy in the dwelling and created a negative space. This was also the belief among some Native American sects as well, thus the round house. Devon County England boast a mere 20,000 homes built of Cob and it is still a small tradition for the bridegroom to build a cob house for his bride before the wedding can take place. This is a report done on a home in B.C. Canada concerning the performance of a Cob house. science-research-report, read it you'll be amazed. Here is more concerning Cob and it's insulative properties.

OK, LETS GET COBBING!

First off, if you're new to the process we suggest that your first project be a small one and not to ambitious. The last thing you want in your back yard is a half built mud structure that looks like something left over from a science experiment that went arie. Start with something small like a small garden wall or a bench or even a cool sculpture like a dog house, just so that you can get the feel for the process. Then it will be off to bread ovens and garden houses and so on, WARNING: COB is highly addictive, you've been warned.

The Formula

muha-ha-ha!!!!

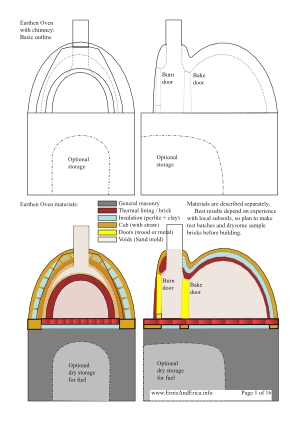

Two-Chamber Earthen OvenThe "Two-Chamber Earthen Oven" book is available here COB-OVEN

|

^Click to enlarge^ ^Click to enlarge^

HOW TO MAKE COB

Cob Formula and things you will need. 1- part clay. 2- parts sand. Water. Straw. Tarp and a test bottle. Digg down into your clay beneath the topsoil 3-6 inches, and then fill a mason or spaghetti sauce size glass jar halfway with your clay and then fill the rest with water and shake it hard to mix it all together, allow it to settle for one day and then figure out your clay to sand proportions, you will need to play with this mix according to your surroundings. Clays have different qualities in every region as far as sand content, but that is the basics on where to start. The sand will settle to the bottom of the jar because it is the heaviest. (This formula is basic and universal, you need to make test bricks with your own soil and adjust it accordingly for maximum strength. i.e. 1- sand to 1 clay, 2 - clay to 1 sand, sometimes you might only have to add water and straw because you soil is already the perfect mix. Make test bricks and allow to dry, then drop them from 4 feet or try to break with your hands, you will see the difference and be able to go from there. I don't add straw for test bricks. Once you find your master mix t try it with straw. On the tarp place 1 shovel of clay, ( if you have a good source of clay on your property and want to use it, make sure that you remove the top soil) Now add 2 shovels of sand to the clay. work it all together with your hands so that it is evenly mixed, After that mound the mixture into a volcano style mound with a hole in the middle. Fill the hole with water and allow it to be absorbed into the mixture. After the water is absorbed you will need to start to knead the mixture together. You don't want the cob to be to wet. Now comes the fun part. Take off your shoes and socks and get on in there, stamp the mixture with your feet like you are making mud wine then pull the tarp back and forth over top of it to roll it around. You need to get the water evenly distributed. You don't want soup. The mixture should be thoroughly wet but still be firm and able to break apart in your hands, but you should also still be able to sculpt it. It's a fine line that only experience will teach you. After this is done spread a layer of straw over the top of the cob mix and repeat the mixing process again until the straw is thoroughly mixed through it. Don't skimp on the straw, this is the binder that holds it all together, put a healthy layer on. And presto you now have cob that is ready to be formed and sculpted. Form balls of the cob to the size of your project, big project, big balls, little project, little balls. Pack them together in the desired form that you wish.Time is of the essence some what, The cob is now starting to set and you need to get it into the place where it is needed so that it can set and dry in its intended manner. You don't want to go to high to quick with cob, the bottom layers need to be able to dry so that they can support the new layers that you will be being adding. After you have accomplished this you will need to make what is called a slip batch which is just clay and water mixed to a slurry consistency. Fill the cracks of your cob balls and smooth out the edges. A general rule of thumb for building with cob is 12 inches a day, but this will differ from project to project. An Oven for instance can be done in one day. Once you have finished forming your project and every thing is okie-dokie, you will need to seal the cob. There are many ways to seal cob and the best one depends upon the final project and its purpose. Generally you would put a layer of a natural plaster on it but this isn't a good idea if the cob will be walked on or handled on a regular basis, if this is the case then you would want to seal it with a natural sealer like linseed. Poke random holes in your project to help prevent cracking during shrinkage. Cob is susceptible to the elements and needs to be protected and out of direct contact with the elements to ensure a longer life span. If you're building a wall or a building you should always put down a stone footing first to protect from erosion. the traditional saying in south England is “All cob wants is a good hat and a good pair of boots”. There is nothing like picking the fresh ingredients out of your own garden to make your own fresh pizza in your own bread oven in your own back yard, See where we're going with this, It's all about self sustenance and Independence from the grid, and its fun too. More on building a Cob oven. http://www.motherearthnews.com/Do-It-Yourself/2002-10-01/Build-Your-Own-Wood-Fired-Earth-Oven.aspx Science-research-report -This is a report done on a home in B.C. Canada concerning the performance of a Cob house.

THE EMARA PALACE Built in the mid 1300's this structure is a true testament to the long lasting sustenance of Cob. Still to this day it is a vital building for Government and tourism.

|

Here are some links to other styles of Eco-nomic building.

.

Straw Bale Houses Log Cabins Yurts Shipping containers

Wj Bingham Log home builders Yurt info 12 container houses

Bale Watch The Out lands Nomad Shelter Shipping living info

House of straw $100 log cabin Wood land Yurts Container home info

Straw Bale

Wj Bingham Log home builders Yurt info 12 container houses

Bale Watch The Out lands Nomad Shelter Shipping living info

House of straw $100 log cabin Wood land Yurts Container home info

Straw Bale